Building

After several years of planning and construction, the time had finally come in March 2023 and we were able to move into our new building.

The move wasn't far - we only had to move to the other side of the street - but it was a massive step forward for us.

By involving all employees and planning down to the smallest detail, we were not only able to adapt the building precisely to our requirements and processes, but also create what is probably one of the most modern production buildings for mould making in the world.

1,121 m²

Production area

481 m²

Office space

803 m²

Storage

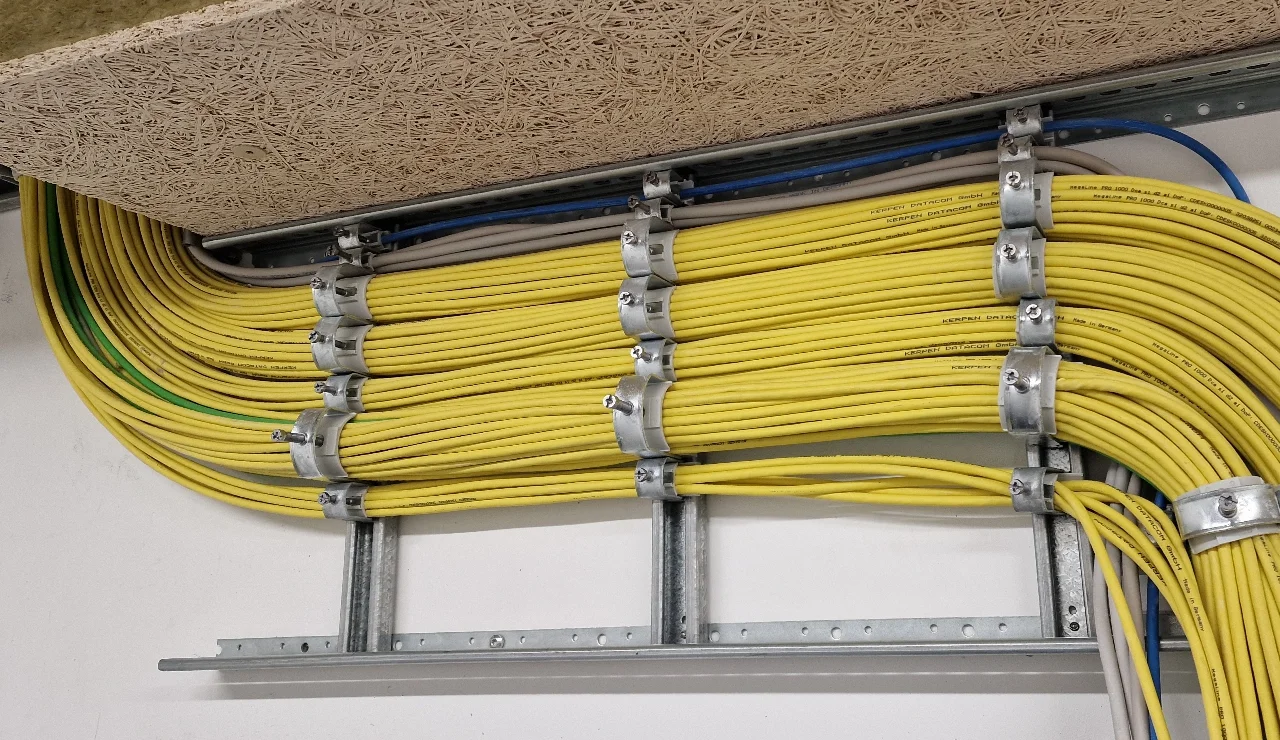

> 23 km

Data cables

> 850

Indoor plants

Highlights

Air-conditioning

The entire building is air-conditioned and actively ventilated.

This not only makes working much more pleasant – especially in the summer – but also enables us to manufacture even more accurately and precisely.

Crane systems

The availability of cranes has always been a bottleneck in production.

However, thanks to a total of 15 cranes in the building, this is a thing of the past and virtually every employee now has their own personal crane at their workplace.

Network

Thanks to high-performance central data distribution points that communicate with each other via modern fibre optic cabling, we are prepared for all future digital challenges.

Sustainability

A good proportion of our electricity requirements are already covered by solar power.

The combination of a high building standard, energy-efficient heat production in a thermal power station with green gas and the generation of hot water from server waste heat brings us significantly forward in terms of sustainability.

Future viability

When planning, we have not only taken into account the requirements right now, but – as far as possible – have already thought one step ahead. As a result, many facilities and rooms are currently larger than necessary. All options will therefore be open to us in the coming years.