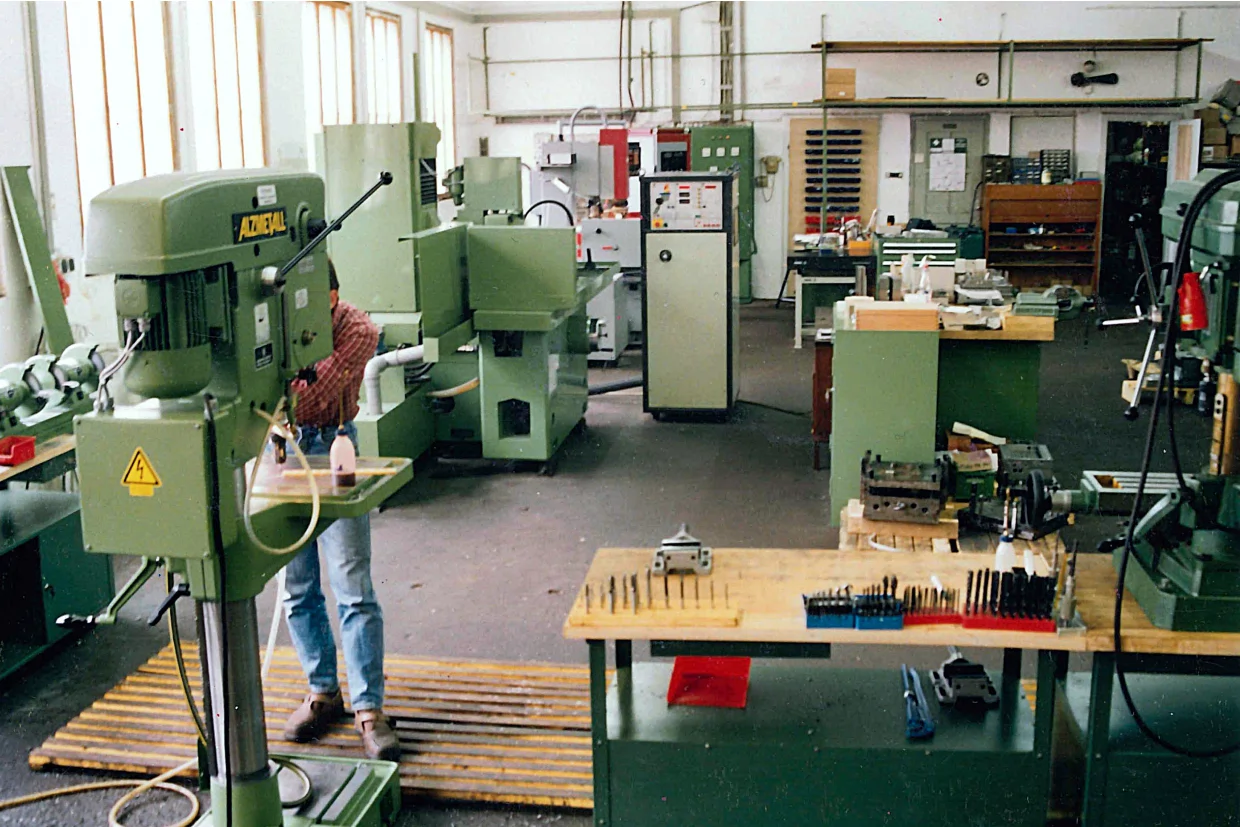

Company History

Purchase of our first wire EDM machine

After five years, we were finally able to wire-cut ourselves, albeit initially "only" with a second-hand AGIE AC 200.

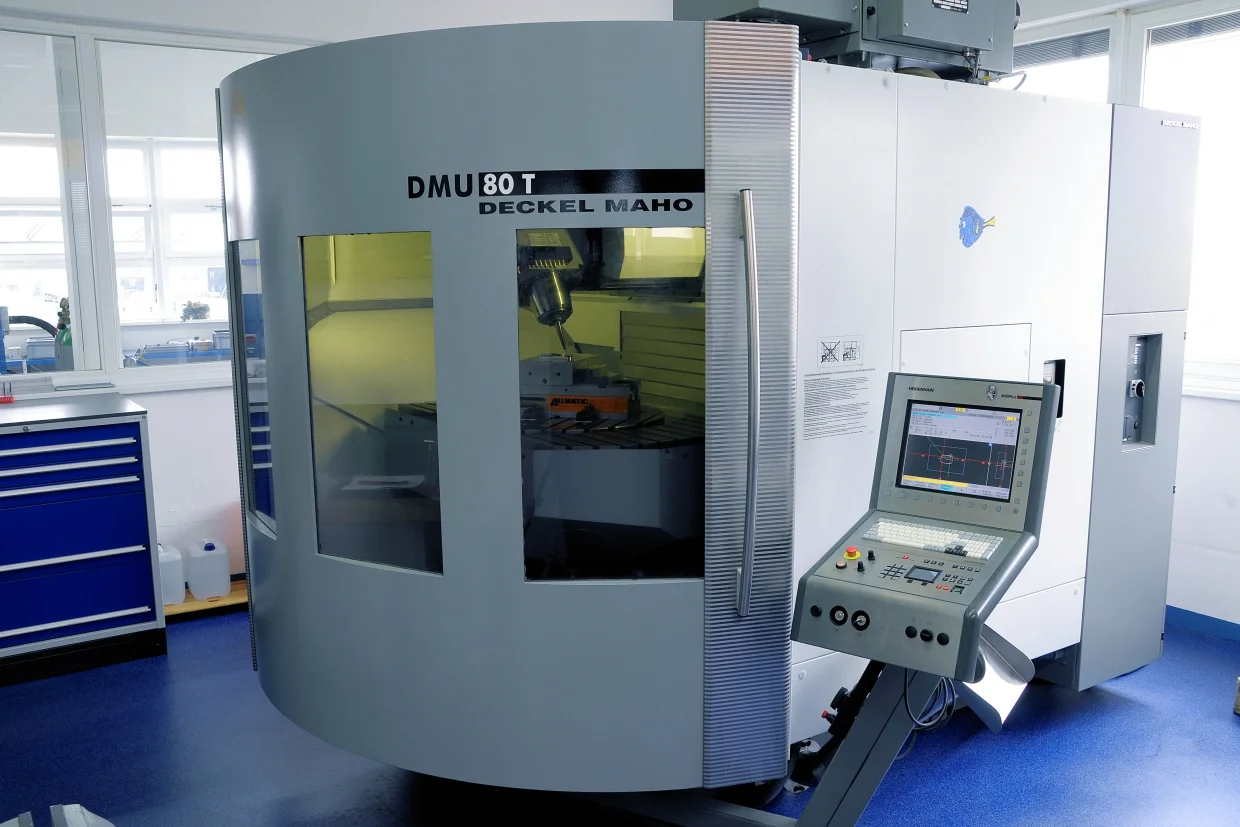

Conversion from conventional eroding to CNC machines

With the turn of the millennium also came the important switch to CNC EDM. A second-hand Ingersoll Gantry 800 replaced our three previous conventional EDM machines.

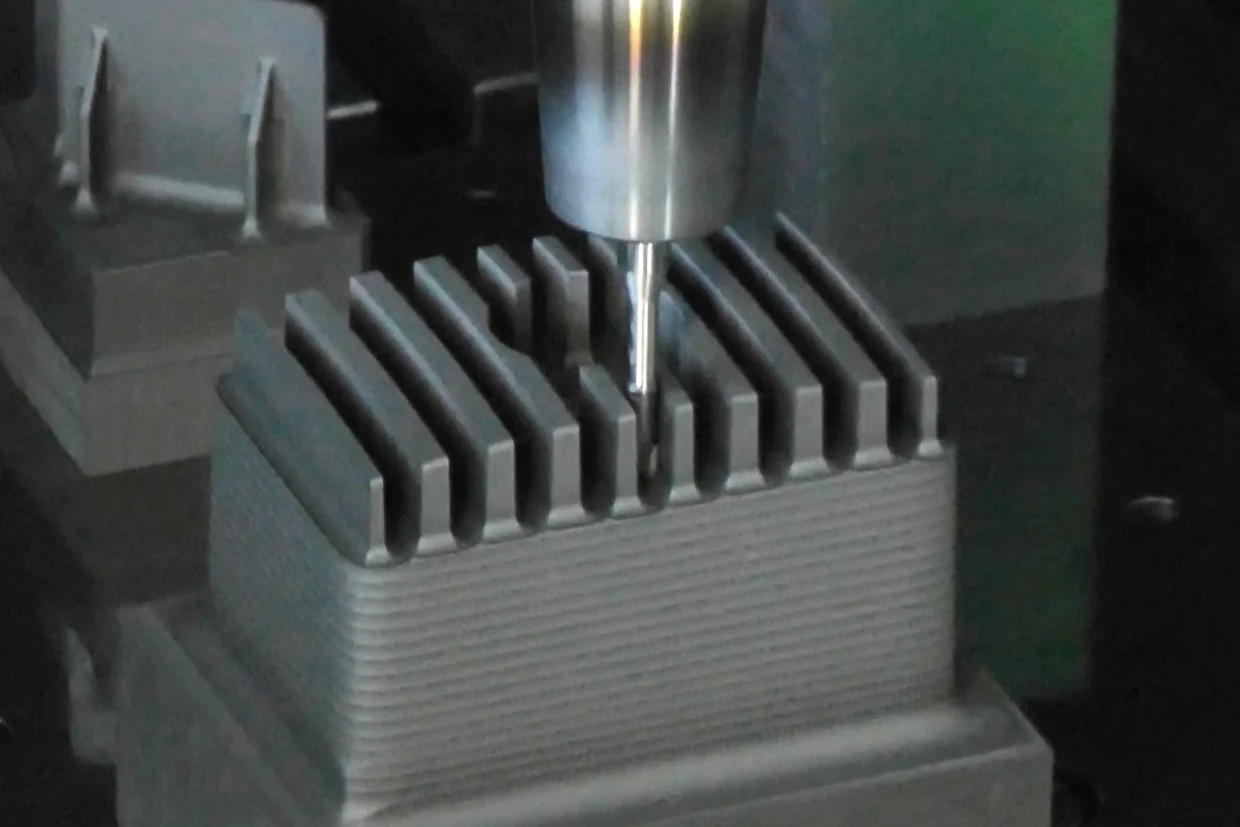

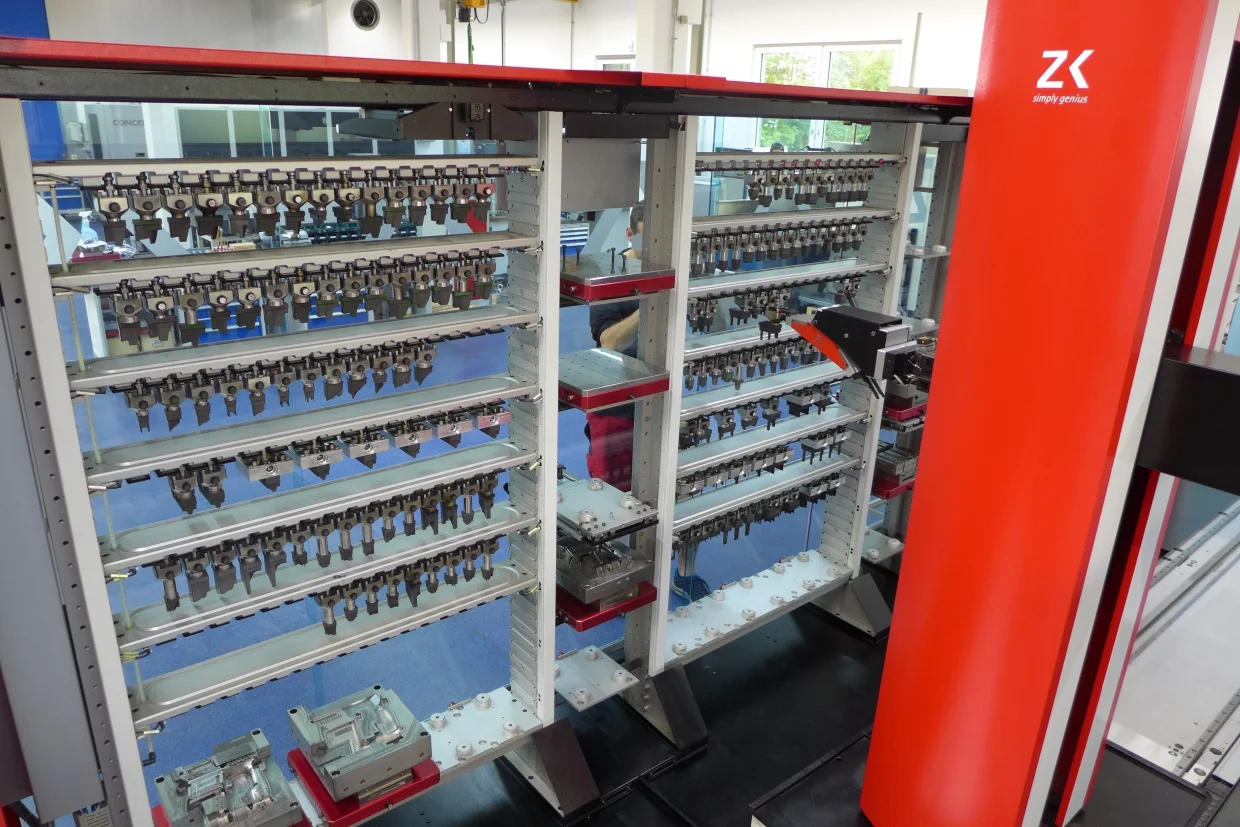

Acquisition of the first automated production cell

In order to relieve our employees and at the same time achieve longer machine running times, we started to automate our production. To this end, we invested in a Zimmer + Kreim EDM centre, which connected two Genius 1000 machines with a "Chameleon" linear robot.

Corona crisis

You can't see it in the picture, but we were delighted that we got through the coronavirus crisis in good shape. Not only were we able to work through it without short-time working or anything like that, we were even able to invest in a new Ziersch ZR 600 cylindrical grinding machine.

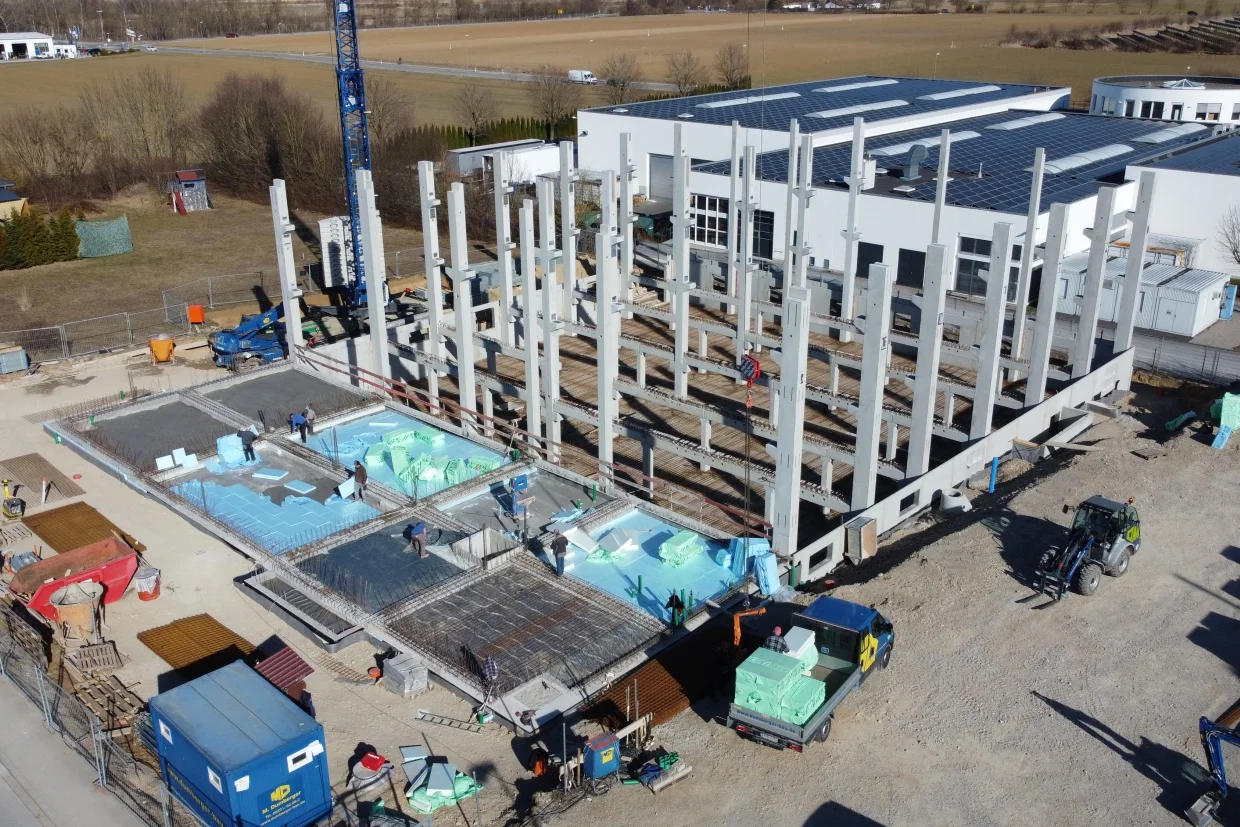

Move to the other side of the street

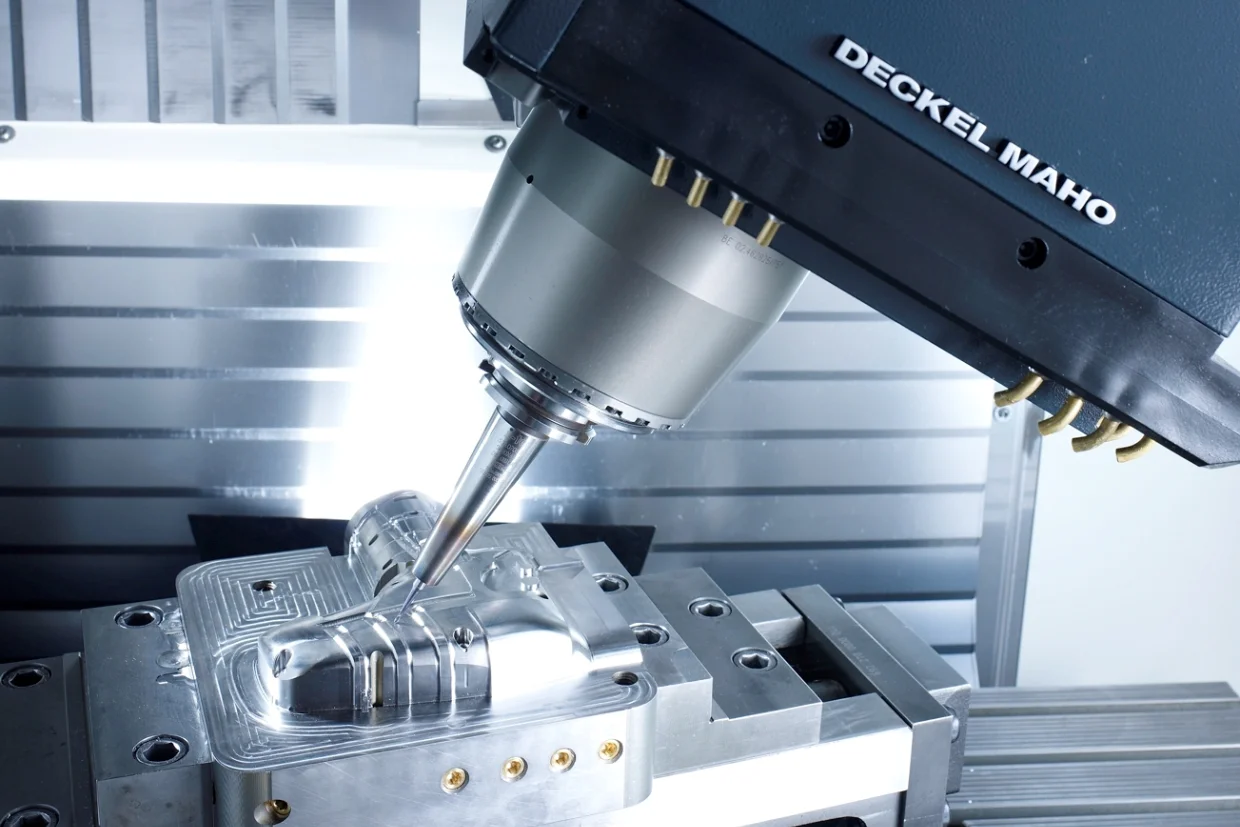

One and a half years later, the time had finally come and we were able to move in. Along with the many modernisations to the building itself (see Building), our EDM cell was also completely overhauled and two of our milling machines were replaced with new Hermle C 42 U machines.